There are many types of forming fabrics, and international classifications are also different. At present, it is roughly classified according to weaving method, wire structure, and fabric level.

1. Distinguish by weaving method

(1) Ring woven forming fabric (also called endless forming fabric). The forming fabric is woven into a loop on the weaving machine without seams, but the equipment required is huge. Because the perimeter of the wire required by the paper machine varies, the polyester forming fabrics currently used on the paper machine are all sheet-woven nets.

According to the length and width required by the paper machine, the forming fabrics are fixed through processes such as forming, cutting and inserting. The two ends are connected to form a ring, which is used for papermaking.

(2) Piece weaving forming fabric. The piece woven forming fabric is also called a terminal forming fabric or a plug-in forming fabric. According to the requirements of the paper mill, the two ends of the forming fabric are inserted with a width of 10-15 cm to form a ring-shaped forming fabric with joints, which is then subjected to heat setting.

After the treatment, the head is cut and polished to make the surface of the forming fabric smooth without affecting the forming quality of the paper sheet.

2. Distinguish by wire structure

(1) Monofilament. The wire material of the forming fabric is a single filament, which is a single filament of various diameters made from a synthetic material after being drawn. Monofilament has excellent abrasion resistance, tensile strength and is very strong. Polyester monofilament is the main raw material for weaving various polyester forming fabric.

(2) Multifilament. Good water absorption and strong tension resistance.

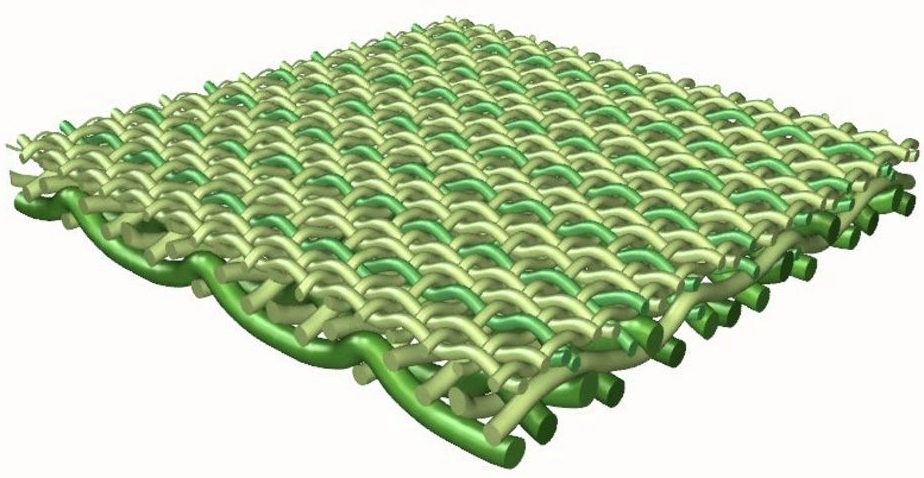

(3) Interwoven mesh fabric. The so-called interwoven mesh fabric is a mesh fabric woven with two kinds of wires: multifilament and monofilament. Generally use multifilament for warp and monofilament for weft, or use monofilament for warp and multifilament for weft.

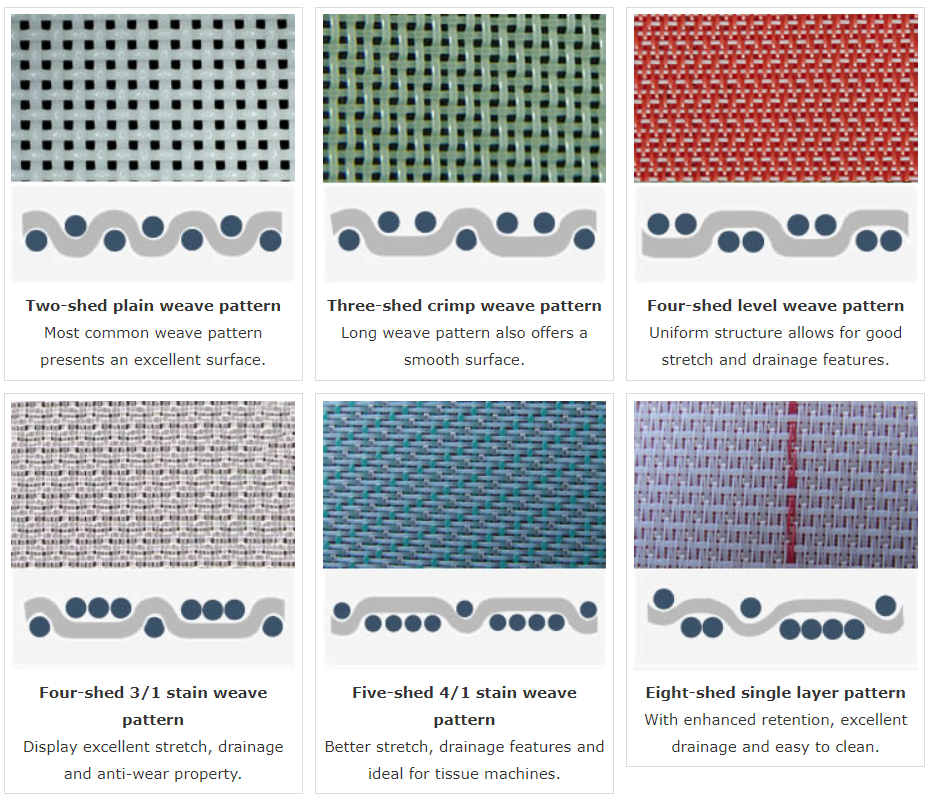

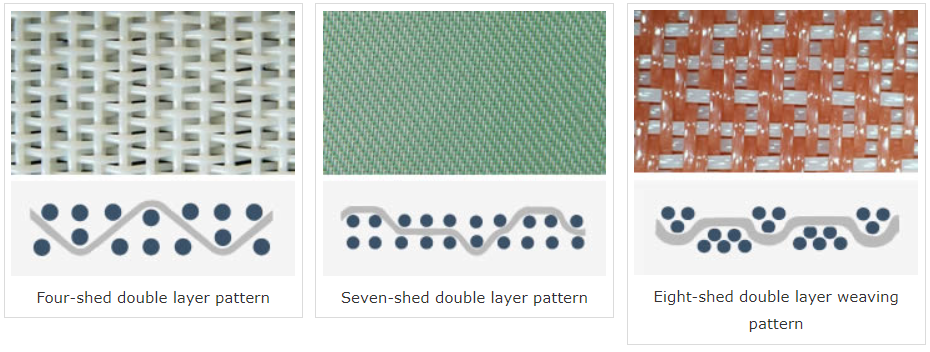

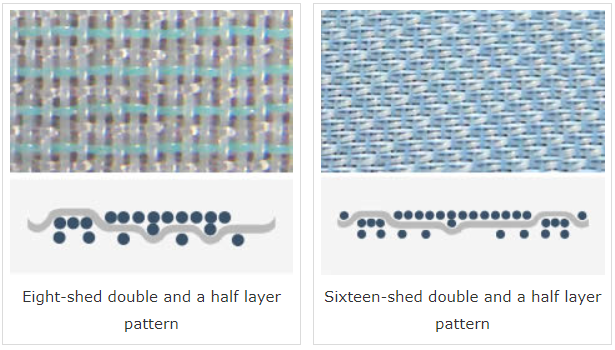

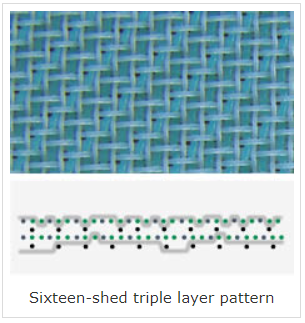

3. According to the fabric layer of the polyester forming fabric

(1) Single layer forming fabric

(2) Double-layer forming fabric

(3) 2.5 layer forming fabric

(4) Triple-layer forming fabric

(5) SSB (self-support Binder) forming fabric.

4. According to the weaving type, polyester forming fabrics can be divided into 4-shed, 5-shed, 8-shed, 16-shed, 24-shed, etc.

5. According to the sliding of the forming fabric wires, it is divided into a warp sliding forming fabric and a weft sliding forming fabric.

The thread of the friction surface of the forming fabric is mainly subjected to sliding friction with warp threads, which is called warp sliding forming fabric. The thread of the friction surface is mainly subjected to sliding friction with the weft thread, which is called the weft thread sliding forming fabric. From the perspective of the service life of the forming fabric, the warp threads generally bear the tension of the mesh, while the weft threads mainly bear the abrasion with the components, so the forming fabric chooses the weft sliding mesh.