The Polyester Mesh Belt is a key component in the wet-laid nonwoven fabric production line, used during the forming and dewatering stages. It acts as the forming wire orforming fabric, providing a stable and uniform surface for fiber deposition and water drainage.

With excellent dimensional stability, smooth surface, and high permeability, polyester mesh belts ensure uniform fiber distribution and consistent product quality.

Description

Wetlaid is a nonwoven fabric manufacturing process that involves the formation of a web of fibers from a liquid suspension or slurry. The process begins with a mixture of fibers, usually consisting of natural or synthetic materials such as cellulose, polyester, or nylon, which is then dispersed in water or another solvent to form a pulp. The pulp is then fed onto a moving conveyor belt or screen, and the excess water is drained away, leaving behind a layer of fibers.

Next, the wet web is passed through a series of rollers, which compress and compact the fibers, creating a more uniform and denser structure. The web is then dried using a variety of methods, such as through the use of heated rollers or by passing it through a hot air oven.

Wetlaid nonwovens are commonly used in a variety of applications, including filtration, insulation, and medical products, as they offer good strength, softness, and absorbency. They can also be engineered to have specific properties, such as water resistance or flame retardancy, by incorporating additives during the manufacturing process.

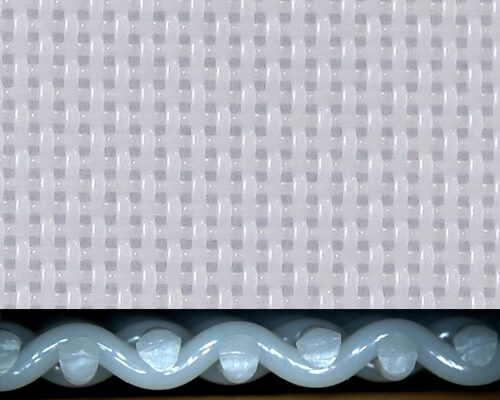

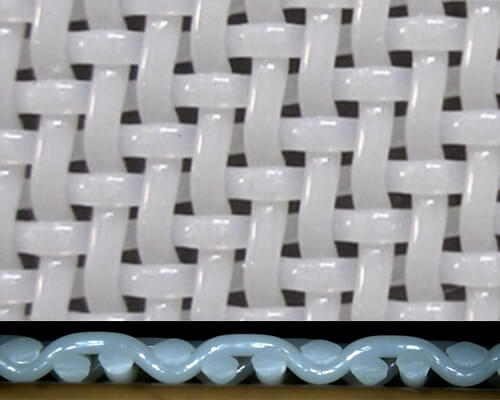

The wetlaid forming belt is woven from high-tensile polyester monofilament yarns, designed to withstand high mechanical loads and frequent washing cycles. In the wetlaid process, the mesh belt is used to support the wet web of fibers, and helps to prevent the wet web from sticking to the conveyor, which can cause tearing or damage to the material.

They can also be designed to have specific characteristics, such as a larger or smaller aperture size, depending on the requirements of the manufacturing process.

Feature

1. Optimum drainage, Excellent fiber retention, Highly resistant against wear.

2. High Fiber Retention: Fine upper surface prevents fiber loss and ensures even formation.

3. Excellent Dimensional Stability: Resistant to stretching and deformation under wet conditions.

4. High Permeability: Optimized drainage efficiency for faster dewatering.

5. Smooth Surface: Guarantees defect-free, mark-free nonwoven surfaces.

6. Chemical and Heat Resistance: Withstands wet-laid process chemicals and drying temperatures.

7. Easy Cleaning: Non-adhesive surface reduces fiber build-up and simplifies maintenance.

8. Customizable: Mesh belts can be tailored to specific manufacturing needs by adjusting the size of the mesh openings or using different materials for the belt.

Application

Polyester forming mesh belts are widely used in various wet-laid nonwoven production lines, including:

1. Wetlaid paper-like nonwoven fabrics

2. Battery separator substrates

3. Industrial filtration materials

4. Glass fiber and carbon fiber wet-laid mats

5. Decorative base materials and synthetic leather substrates

Specifications

| Model | Wire diameter | Density | weight | Aperture Radial/latitude | Air Permeability(m3/m2h) | ||

| (mm) | (wire/centimeter) | (kg/m2) | (mm) | ||||

| warp | weft | warp | weft | ||||

| PFM-Wetlaid-09603 | 0.5 | 0.6 | 10.5 | 9.2 | 0.65 | 0.45/0.48 | 8300 |

| PFM-Wetlaid-09502 | 0.5 | 0.5 | 9.5 | 9 | 0.63 | 0.55/0.53 | 10100 |

| Custom specification is available if you can't find the suitable size. | |||||||

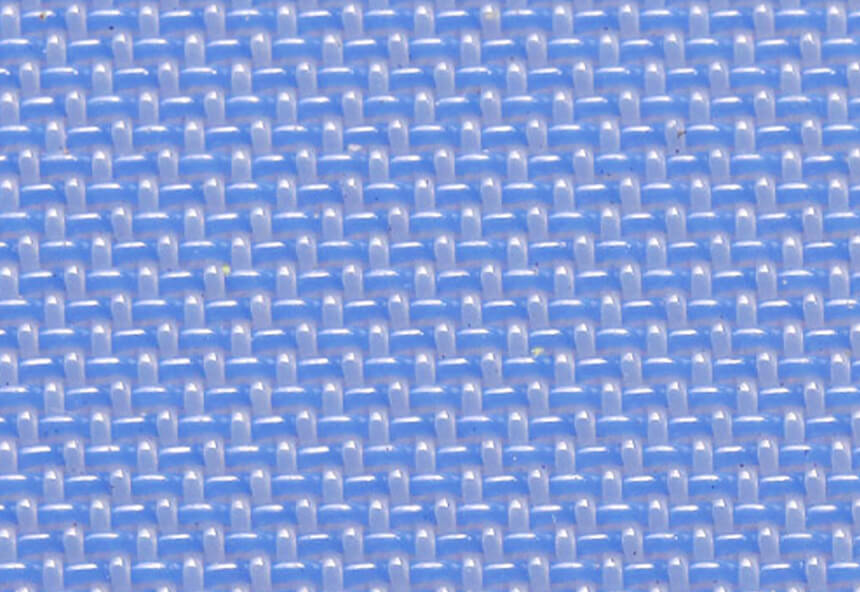

09502

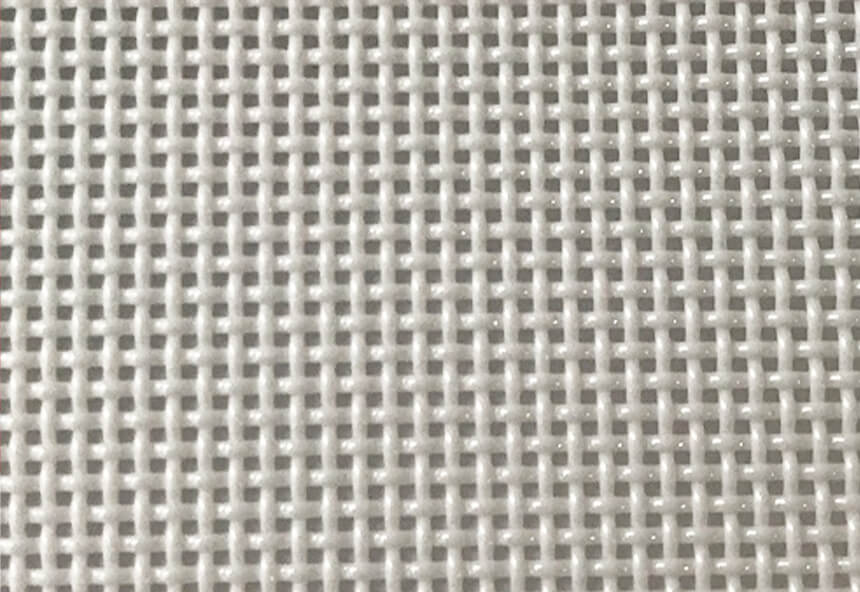

09603