The Polyester Mesh Belt for Air-through Bonding Nonwoven Fabric, also known as the Hot Air Nonwoven Mesh Belt, is a specialized functional conveyor belt designed for air-through bonding lines. It operates inside the hot air oven, supporting and conveying the fiber web while allowing hot air to penetrate evenly through the mesh for efficient thermal bonding and consolidation of the nonwoven fabric.

Description

Air-through bonding is a thermal bonding process used in nonwoven fabric production. In this process, hot air is evenly passed through a fiber web to melt the low-melting components (such as the PE part of ES fibers), which bond with high-melting fibers to form a stable and durable nonwoven fabric.

The air-through bonding process allows hot air to pass through the fiber web from top to bottom or vice versa. The thermoplastic fibers partially melt and bond at their contact points. After cooling, a soft, bulky, and breathable nonwoven fabric is formed.

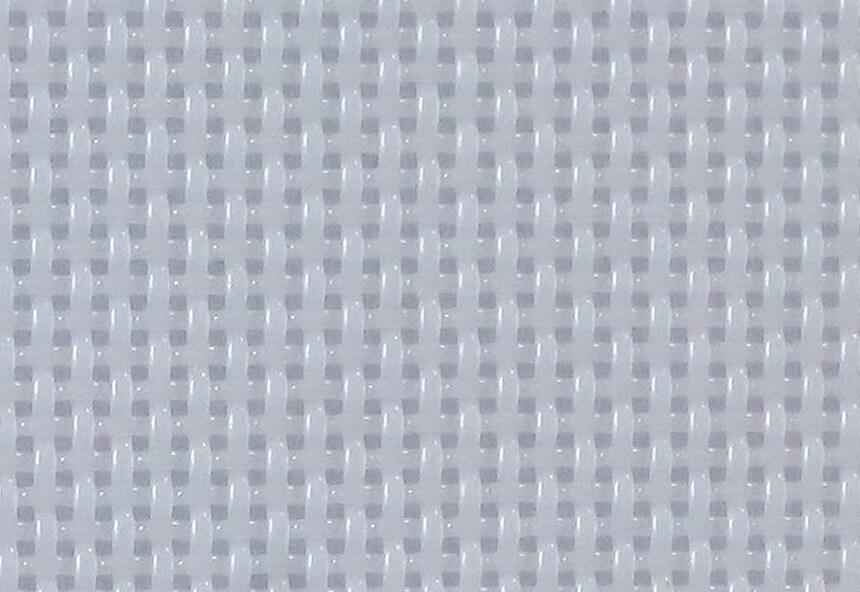

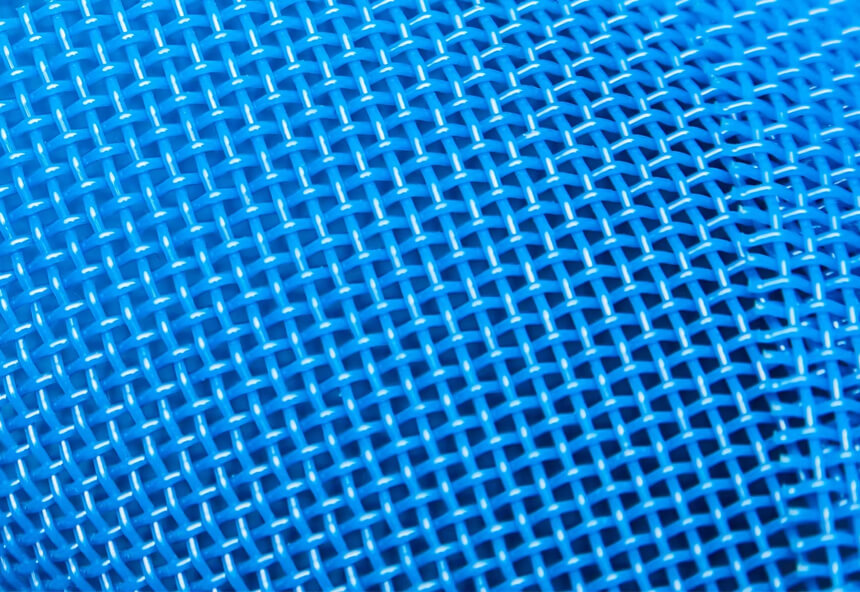

The Hot Air Nonwoven Mesh Belt is woven from high-tenacity polyester monofilaments and stabilized through heat-setting and surface finishing treatments, providing excellent dimensional stability and heat resistance.

Depending on the machine configuration and product requirements, it can be designed in single-layer or double-layer structures.

Feature

1. High air permeability ensures uniform air distribution through the fiber web.

2. Excellent heat resistance, continuous working temperature of 150–180°C.

3. Smooth surface ensures uniform fabric thickness without marking.

4. Outstanding dimensional stability with minimal elongation or shrinkage.

5. Easy to clean, non-fibrous adhesion, long service life.

6. Customizable width, joint type, and reinforced edges according to machine design.

Application

The hot air nonwoven mesh belt is widely used in various nonwoven production lines, especially in:

1. Air-through bonded nonwoven fabrics.

2. Hygiene products (topsheets of diapers and sanitary napkins).

3. Thermal setting zones in meltblown and spunbond composite lines.

4. Filtration and medical protective materials production.

Specifications

| Model | Diameter ( mm ) | Density (wire/centimeter) | Air Permeability(m3/m2h) | ||

| Warp | Weft | Warp | Weft | ||

| PFM-HA-06702 | 0.7 | 0.7 | 6.3 | 6.3 | 11000 |

| PFM-HA-09502 | 0.5 | 0.5 | 10 | 10 | 10100 |

| PFM-HA-07502 | 0.5 | 0.5 | 7.5 | 7.5 | 10000 |

| PFM-HA-05602 | 0.6 | 0.6 | 6 | 6 | 18000 |

Custom specification is available if you can't find the suitable size. | |||||