PFM Screen can customize some special purpose mesh belts for customers, including antistatic mesh belts with conductive wires, alkali-resistant mesh belts of special materials, and pulp washing mesh fabric for special purposes, etc.

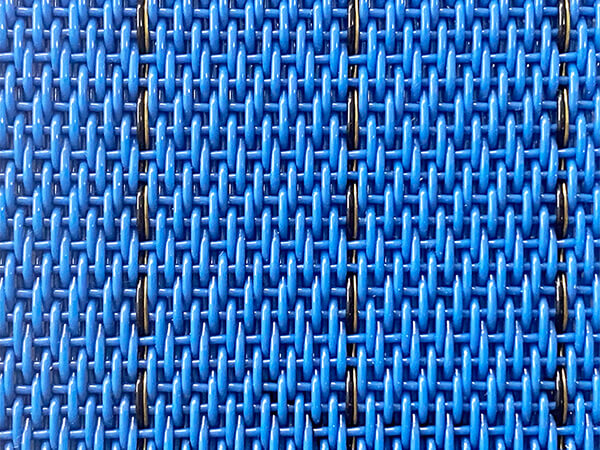

Anti Static Conveyor Belt

The anti static conveyor belt is woven by synthetic fiber (usually PET) combined with antistatic carbon/bronze/stainless steel wire.

The anti static conveyor belt is specially designed for electrostatic sensitive industries. For example, in the production of non-woven fabrics and wood chip fiberboards, the friction between the processed material and the conveyor belt/or the conveyor belt and the slider bed/or dry ionized air usually generates static charges . Although the quiescent current is usually low in intensity, it can be the cause of problems, such as reducing efficiency and product quality when lightweight products adhere to the belt surface, or there is a risk of combustion in an explosive environment.

These anti static conveyor belts drive and dissipate the surface static electricity accumulated during operation. This specially crafted belt helps eliminate polymer spots attached to the belt surface and the risk of sparks that cause a deflagration hazard.

Features of Anti Static Conveyor Belt

The static charge in the conveyor belt may be caused by friction between the conveyor belt and the slider bed and/or the movement of the conveyed product or due to the ionization of the air (dry and dusty environment). Although the quiescent current is usually low in intensity, it can be the cause of problems, such as when a lightweight product sticks to the top cover of a conveyor belt. Where there is a risk of sparks, it can also be dangerous in environments sensitive to deflagration.

Therefore, the anti static conveyor belt woven by the combination of wear-resistant PET yarn and embedded carbon/bronze/stainless steel yarn can drive and dissipate the electric charge. This specially crafted belt helps prevent static electricity from accumulating, eliminating polymer spots attached to the belt surface and the risk of sparks that can cause a deflagration hazard.

The special woven pattern makes our conductive craft belt slip resistant on rough surfaces, and at the same time has good fabric release at the end of the belt. In addition, it makes the air permeability adjustable to meet various requirements for different purposes.

The thicker weft yarn ensures the firmness of transverse bending resistance.

Good heat-fixing post-processing, to achieve excellent running performance, to ensure straight-line running, minimum deviation, and stable size.

Anti Static Conveyor Belt Woven Method

The woven mesh conveyor belt usually joint in pin seam, double pin seam, endless woven etc. The invisible and well closable joint is critical to get sophisticated non-marking products.

Anti Static Conveyor Belt Application

Antistatic mesh belt is widely used in airlaid, spunlaid, wetlaid & drylaid nonwoven forming, wood fiberboard, dust-free paper, chemical fiber, and other industries.

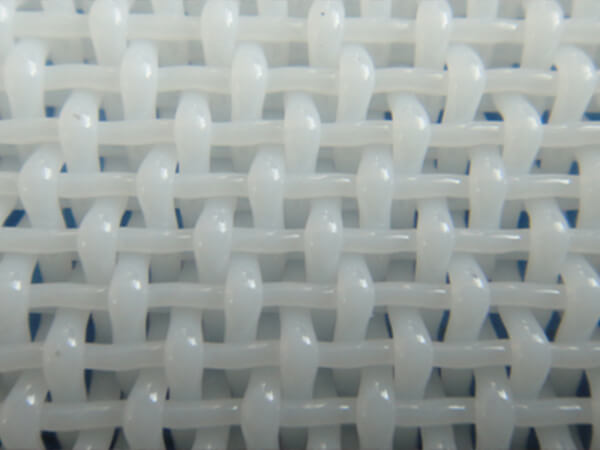

Alkali-Resistant Mesh Belt

The alkali-resistant mesh is woven from nylon or PPS monofilament. Generally, it can be used under alkaline conditions where the alkali content is ≥20% sodium hydroxide. Alkali-resistant mesh also has good tensile strength, high-temperature resistance, also prominent abrasion resistance, widely used in the pharmaceutical and chemical industries.

Pulp Washing Mesh Fabric

Pulp washing fabric includes 2-shed and 3-shed type, they are mainly used in washing equipment and special field. Such as wash coal, vacuum wash plasm machine and drum type wash plasm machine, paper pulps making, sulfate pulp packing and cardboard pulp and fiberboard plants mining industry, food industry filtion and dryer etc.