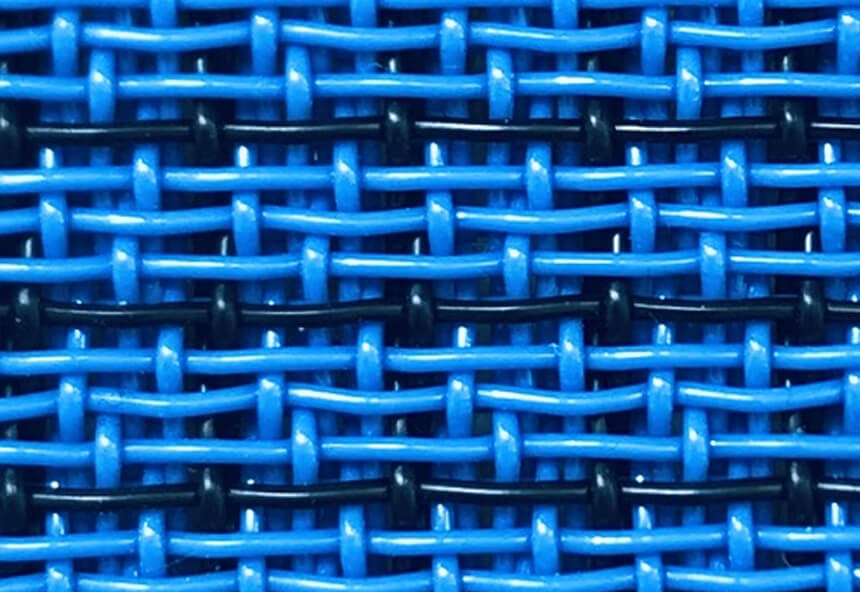

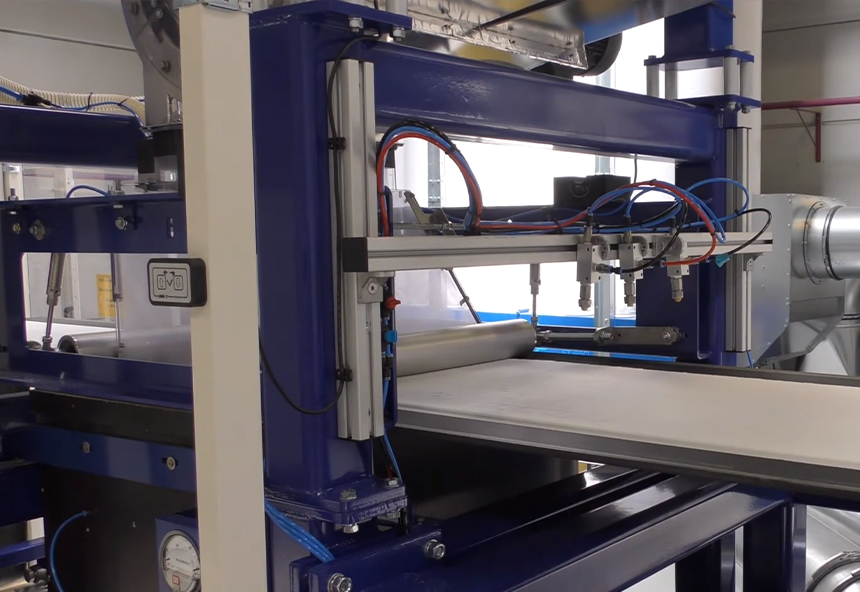

Airlaid mesh belts are designed specifically to process Airlaid Structures more efficiently, effectively and with less waste. The Airlaid mesh belt is a porous polyester mesh conveyor belt that serves as the forming and conveying surface in the airlaid process. It collects and transports the fiber web after fibers are dispersed and laid down by air flow.

Description

Airlaid is a nonwoven textile material that is produced by air-laying fibers onto a moving conveyor belt using a dry-laid process. In this process, a web of fibers is formed by suspending them in air and then depositing them onto a moving belt with the help of a vacuum. This creates a highly absorbent and durable material that is widely used in a variety of applications such as hygiene products, food packaging, and industrial wipes.

Airlaid can be made from a wide range of fibers such as pulp, synthetic fibers, or a blend of both. The fibers are first opened and fluffed up, and then transported by air to the moving conveyor belt. Once the fibers have been deposited onto the belt, they are bonded together using various methods such as thermal bonding, chemical bonding, or mechanical entanglement. The resulting material is highly absorbent, soft, and has good strength and durability.

Airlaid materials are commonly used in the manufacture of hygiene products such as diapers, feminine care products, and adult incontinence products. They are also used in the food packaging industry as tray liners, absorbent pads, and wraps for meat and poultry. Additionally, airlaid materials are used in industrial applications such as cleaning wipes, oil absorbents, and filtration media.

Feature

The airlaid mesh belt has several advantages and applications in the production of airlaid nonwoven materials. Some of these are:

1. High strength and durability: Airlaid mesh belts are typically made from high-strength polyester monofilament , which makes them strong and durable. This allows them to withstand the high tension and stress that is generated during the airlaid process.

2. Good drainage and airflow: The open mesh design of the airlaid mesh belt allows for good drainage and airflow. This is essential in the airlaid process, as it allows air to pass through the belt and carry the fibers to the conveyor belt, ensuring that they are deposited evenly.

3. Prevents fiber buildup: The open mesh design of the airlaid mesh belt also helps to prevent the buildup of fibers on the belt, which can lead to blockages and downtime in the production process.

4. Easy to clean: Airlaid mesh belts are easy to clean, which helps to maintain production efficiency and minimize downtime.

5. Excellent electrical conductivity: High static discharge for excellent formation and sheet release.

Application

Some common applications of airlaid mesh belts include the production of:

1. Hygiene products such as diapers, feminine care products, and adult incontinence products.

2. Food packaging such as tray liners, absorbent pads, and wraps for meat and poultry.

3. Industrial products such as cleaning wipes, oil absorbents, and filtration media.

Specifications

| Type | Wire diameter (mm) | Density (wire/centimeter) | Weight | CFM/127Pa | Caliper | ||

| Warp | Weft | Warp | Weft | (kg/m2) | (mm) | ||

| PFM-Airlaid-01 | 0.5 | 0.5 | 20.5 | 16 | 1.2 | 700 | 1.8 |

| PFM-Airlaid-02 | 0.43×0.70 | 0.7 | 18 | 11 | 1.05 | 900 | 2.1 |

| PFM-Airlaid-03 | 0.52×0.50 | 0.3×0.70 | 16 | 13 | 1 | 750 | 1.6 |

| PFM-Airlaid-04 | 0.52×0.50 (antistatic) | 0.45×0.60 | 20 | 15 | 1.01 | 600 | 1.6 |

| PFM-Airlaid-05 | 0.38×0.52 | 0.50×0.60 | 20.5 | 18 | 1.1 | 650 | 1.45 |

| PFM-Airlaid-06 | 0.5 | 0.5 | 8.5 | 9 | 0.52 | 900 | 0.95 |

| PFM-Airlaid-07 | 0.68 | 0.7 | 7 | 6.5 | 0.62 | 850 | 1.3 |

| Custom specification is available if you can't find the suitable size. | |||||||