In modern wood-based panel manufacturing—particularly Medium-Density Fiberboard (MDF), Particle Board (PB), and Oriented Strand Board (OSB)—the preheating stage is critical for ensuring uniform board density, surface quality, and production efficiency. At the heart of this stage lies a specialized component: the Polyester Spiral Mesh Belt.

Whether transporting the fiber mat or ensuring consistent temperature exposure, polyester spiral mesh belts (with or without wire filler) are indispensable. In this blog, we explore the applications of preheating belts in the wood industry, the roles of spiral mesh belts with wire filler in MDF, PB, and OSB production, and how to select the right type for your preheating system.

Before the fiber or chip mat enters the hot press, it must undergo preheating—a stage that serves several important functions:

Reducing moisture content

Increasing core temperature for faster pressing

Improving resin activation

Enhancing board homogeneity

This process relies on hot air, steam, or contact heating, and polyester spiral mesh belts act as the medium for conveying and processing the fiber mat through the preheating zone.

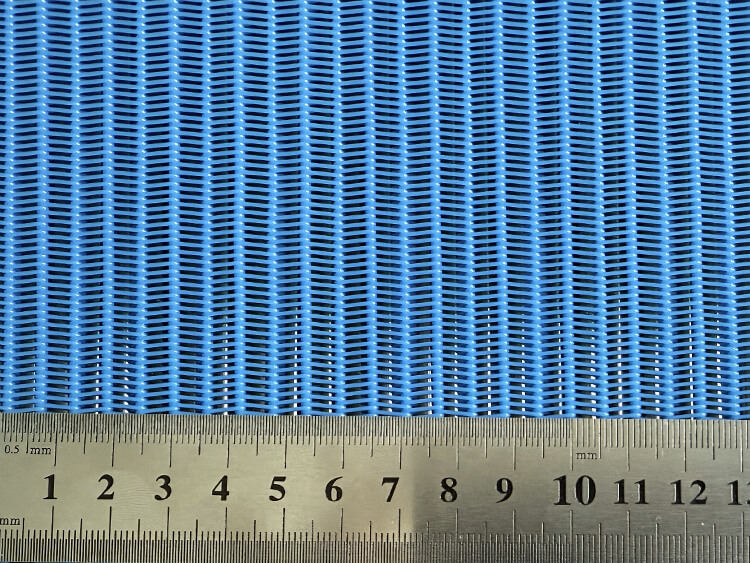

Polyester spiral mesh belts are made of polyester monofilaments woven in a spiral structure. These belts feature:

High dimensional stability

Good air permeability

Resistance to high temperatures and chemicals

Smooth surface for mat transport

In more demanding applications, wire filler (polyester or carbon-loaded flat wire) is inserted into the spirals to adjust the belt’s properties—most notably, to reduce air permeability and enhance mat stability.

In the Wood-based panel production process, raw wood fibers are mixed with resins and waxes, then formed into a fiber mat. Before hot pressing, this mat undergoes preheating to improve temperature uniformity and reduce pressing time. This is where spiral mesh belts come into play.

Wire filler—commonly polyester flat wire or carbon-loaded black polyester—is inserted into the spiral to reduce air permeability and enhance other belt properties.

Key Benefits of Wire Filler:

Controlled Air Permeability: Helps regulate airflow for better preheating efficiency and reduced heat loss.

Improved Mat Stability: Reduces mat shifting, fiber loss, and deformation.

Enhanced Belt Surface Uniformity: Offers a smoother and more solid contact area, leading to more consistent board thickness.

Antistatic Properties: Carbon-loaded fillers help discharge static electricity in dusty environments (especially in MDF and PB lines).

Choosing the correct spiral mesh belt involves balancing air permeability, mechanical strength, temperature resistance, and belt lifetime. Below is a selection guide tailored to MDF applications:

| Selection Factor | Recommended Option |

| Temperature Resistance | Polyester monofilament belts withstanding 120–160°C continuous exposure |

| Air Permeability | Low permeability belts with wire filler for uniform preheating and moisture control |

| Filler Material | Polyester flat wire or carbon-filled black polyester for stability and antistatic use |

| Seam Type | Spiral loop seams or pin seams for easy installation and minimal marking |

| Loop Size | Large loop belts offer better airflow and smoother transport |

| Application Focus | MDF: Low air permeability |

| PB: Medium permeability | |

| OSB: High strength & stability |

Upgrading or properly selecting preheating spiral mesh belts for MDF and similar production lines brings significant benefits:

Reduced Pressing Time

Improved Final Board Quality

Lower Energy Consumption

Fewer Surface Defects

Higher Production Efficiency

Polyester Spiral Mesh Belts, especially those equipped with wire filler, play a central role in the preheating process of MDF, PB, and OSB board production. Their ability to deliver consistent temperature exposure, reduce moisture content, and stabilize the fiber mat directly affects the final product’s quality and production throughput.

For MDF manufacturers in particular, selecting the right preheating belt—based on air permeability, belt structure, and filler material—is essential for achieving optimal performance, minimizing downtime, and improving product consistency.