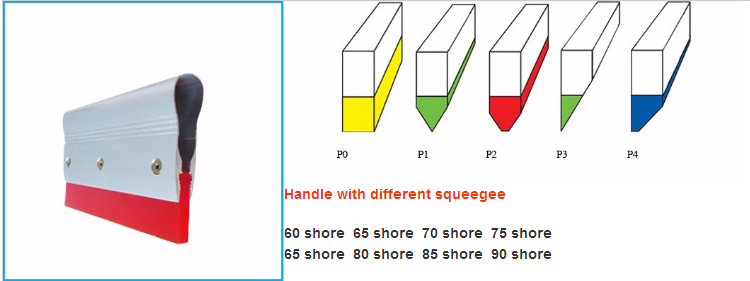

The squeegees scraping is usually made of polyurethane, and the durometer is used to measure the soft hardness of the squeegee scraper. The hardness(duro), size and shape of the scraper determine the flexure, flexibility and pressure of the scraping. The hardness range from 55 degrees to 90 degrees (Shore A). The hardness value was measured by the Shore A hardness tester. 55A-65A is low hard rubber scraper, 66A-75A is medium hard, and more than 75A is high hard. The high hardness rubber scraping is very beneficial to the first three functions of rubber scraping. It presses the ink into the screen and transfers the ink from the fine mesh to the substrate, and maintains the line of different squeegee blade edge shapes. And the quality of the scraping is also high in the rough and uneven surface.

With the development of paper industry, paper making machinery and equipment are constantly developing towards a wider direction of the width of paper. At present, toilet paper, newsprint and cultural paper machine design speed exceeded 2200m/min, the design speed of wrapping paper machine has reached 1500m/min, and the ability of China's papermaking machinery autonomy is still relatively backward, high speed paper machine and paper machine paper woven fabric mainly depends on import, become a bottleneck restricting the development of China's paper industry.

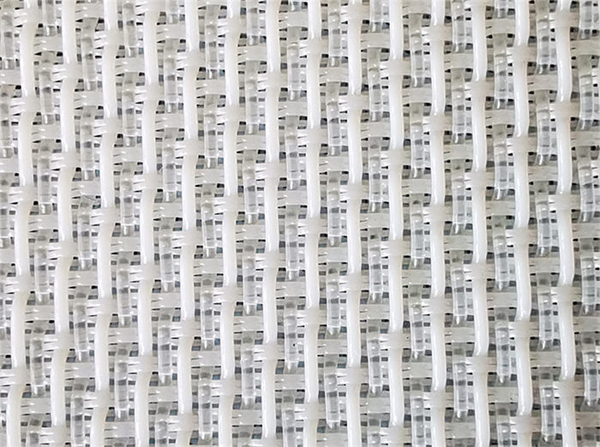

In order to achieve the goal of localization of high-speed paper machine woven fabric, BEIJING PFM SCREEN has developed three layers of paper making fabric.

The triple-layer forming fabric is designed based on the upper, middle and lower three layers. The upper layer adopts the meridian, weft and plain weave structure with a smaller diameter. It improves the retention rate of fine fiber and filler, improves the paper evenness and smoothness of the paper, and marks the web lightly and easily peel off. The lower layer adopts the warp and weft of the thicker diameter to improve the stability and service life of the forming net structure. In the middle layer, the two layers of the upper and lower layers are tightly connected by a pair of weft lines, so that the upper and lower two layers do not produce relative rubbing and sliding.

The triple-layer forming fabric has good quality, strong dehydration ability, high vertical and horizontal stiffness, good running stability and long service life. It has been widely applied to high speed paper machine.